Expert Mold Design: Leading Solutions in Houston

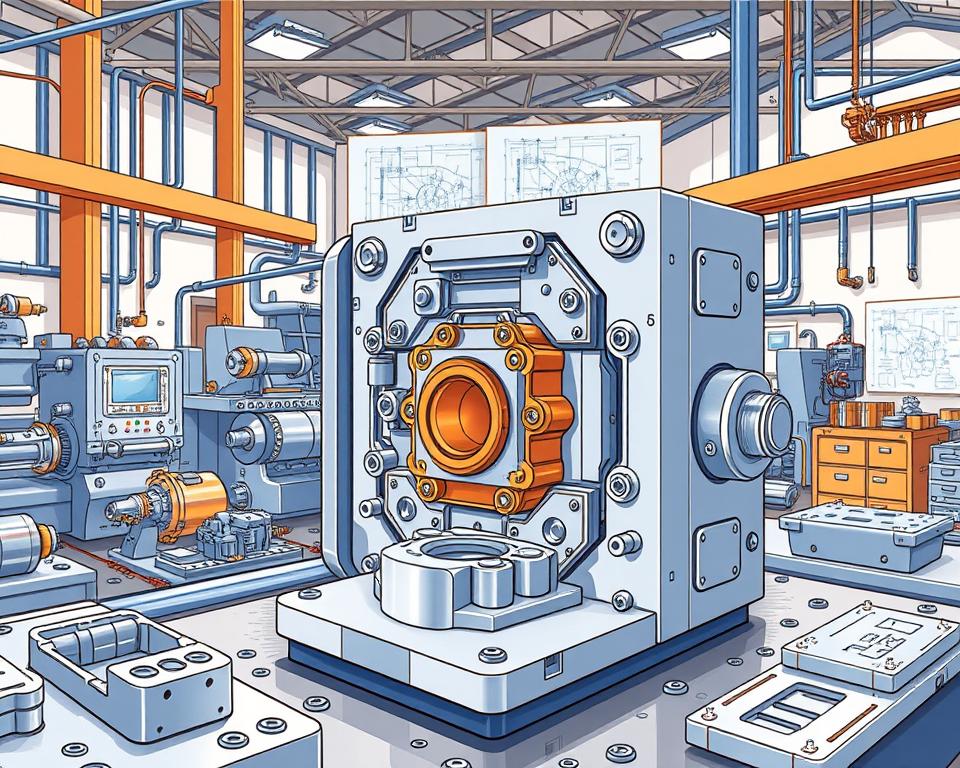

It’s projected that the global injection molded plastics industry will swell to $440 billion by 2025. These figures emphasize the critical role of professional mold design. They create high-quality custom mold designs for diverse industries. Among Houston companies, Lowrance Machine is renowned for mold design. They offer innovative solutions for automotive, aerospace, and consumer products.

With CAD and 3D-printing at its core, Lowrance Machine. Their experts guarantee both accuracy and speed throughout molding. Their seasoned experience and engineering prowess make them a dependable collaborator. Explore how their industrial molds Houston services can improve your projects and meet today’s market demands.

Why Mold Design Services Matter

Mold design services are vital in the manufacturing world, affecting product quality and operational efficiency. Mold design dictates product performance and durability. By prioritizing professional mold design, firms reduce costs and improve quality measures.

Seasoned professionals at Lowrance Machine illustrate the benefits of expertise. They dive deep into client needs and work hand-in-hand to craft custom solutions. Through CAD-driven 3D modeling, they produce molds of exceptional standard.

Choosing top-notch mold design services boosts product performance and drives business success. With optimized mold design, manufacturing runs smoothly and firms gain market advantage.

Mold Design Houston: Types of Services Offered

Lowrance Machine offers a wide range of mold design Houston services, tailored to meet specific industry needs. Knowing the different types of mold services helps businesses choose the best for their projects. Key categories include:

- Design Services: Tailored mold designs crafted to precise specs.

- Prototyping: Early-stage mold prototyping to validate designs.

- Houston Injection Mold Services: High-quality injection molds designed for durability and precision, ideal for various manufacturing applications.

- 3D CAD Modeling: Advanced CAD to develop exact 3D mold prototypes.

- Mold Repair & Upkeep: Services aimed at extending the lifespan of existing molds through essential repairs and maintenance.

Each service is designed to streamline production, improve product quality, and ensure cost-efficiency. With clarity on service options, businesses can align mold solutions with their production goals.

Benefits of Choosing Professional Mold Design Experts

Engaging professional mold design teams offers significant process improvements. These benefits include enhanced accuracy, durability, and efficiency. Tailored molds ensure top-notch quality and repeatable outcomes.

Experienced mold design experts offer insights that streamline production. They align molds with regulatory and bespoke requirements. Working together drives creative solutions and lengthens product durability.

Cost-effectiveness is a significant benefit. Cutting-edge methods slash material waste and speed up delivery. Such efficiencies translate into meaningful cost reductions. Swift design workflows speed time-to-market, sharpening competitive positioning.

In summary, specialized mold design companies provide critical support for manufacturers. They focus on boosting throughput and product excellence.

Innovative Techniques in Mold Design

Technological progress has revolutionized mold design. At the forefront, Lowrance Machine applies state-of-the-art methods. These innovations boost productivity and improve product quality. High-end tools simplify bespoke mold crafting while reducing expenses.

3D-print-driven prototyping excels at rapid, complex mold creation. It significantly reduces material waste compared to traditional methods. Simulation platforms enable virtual mold testing and enhancement for superior performance and throughput.

In Houston, mold design experts are embracing these modern strategies. Firms achieve market edge through digital design and high-tech manufacturing. They facilitate flexible, rapid-response mold development to satisfy diverse applications.

| Technique | Description | Benefits |

|---|---|---|

| 3D Printing | Utilizes additive manufacturing to create molds rapidly. | Accelerates turnaround and minimizes waste. |

| Virtual Testing Tools | Enables digital prototype testing and refinement. | Improves exactness and streamlines operation. |

| Digital Design Tools | Utilizes CAD/CAM for exact design work. | Facilitates customization and adaptation. |

Wrapping It Up

Mold design services are critical for businesses aiming at efficient manufacturing and high-quality production in Houston. These services bring specialized know-how to overcome mold design hurdles. They customize approaches to align with specific business goals.

As a leader in accuracy and client partnership, Lowrance Machine stands out. Custom designs and modern tools offered by these experts keep producers competitive. Working with mold design experts improves product quality and streamlines operations.

Opting for professional mold design in Houston balances high standards with operational efficiency. Firms can deliver on client needs while improving their market position. Adopting these specialized services is vital for manufacturers aiming to succeed in today’s competitive environment.