The Ultimate Guide to China Injection Molding Sourcing

The important meeting has recently finished, your new product is a go, the timeline is aggressive, and the budget is, let’s say, constrained.. And suddenly someone—perhaps your superior or the finance head—says the fateful words that make any project manager’s heart skip a beat: “We should look at sourcing this from China.”

Naturally, you agree. It makes sense on paper. The cost savings can be huge. However, your brain is racing with concerns. You’ve heard the stories, haven’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It feels like walking a thin line between big savings and total project failure.

However, here’s the reality. Procuring plastic mold needn’t be a roll of the dice. It’s simply another project with clear steps. And as with any project, success depends on your methodology. It’s less about finding the absolute cheapest quote and more about finding the right partner and managing the process with your eyes wide open. Ignore the nightmare anecdotes. Let’s walk through a real-world playbook for getting it right.

Initial Step: Prepare Your Information

Before searching suppliers or opening Alibaba, nail down your requirements. Honestly, more than half of all overseas manufacturing problems start right here, with a weak or incomplete information package. You can’t expect a factory on the other side of the world to read your mind. It’s akin to asking someone to price-build “a structure” with no details. You’ll get wildly varied quotes that are useless.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. This package is your project’s foundation.

What belongs in your RFQ?

First, your 3D CAD files. They cannot be skipped. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. This is where you call out the stuff that a 3D model can’t communicate. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

Then specify the material. Avoid generic terms like “Plastic.” Even “ABS” alone is too vague. Get precise. Call out SABIC Cycolac MG38 (black), for example. Why? Because plastic grades vary by the thousands. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

Your supplier might propose substitutes, but you must set the baseline.

Finally, include the business details. What’s your forecasted annual volume (EAU)? A supplier needs to know if they’re quoting a tool that will make 1,000 parts in its lifetime or 1,000,000 parts a year. Tool style, cavity count, and unit cost are volume-driven.

Hunting for the Best Supplier

Now that your RFQ is pristine. who will you target? The internet has made the world smaller, but it’s also made it a lot noisier. Finding suppliers is simple; finding quality ones is tough.

Your search will likely start on platforms like Alibaba or Made-in-China.com. These are great for casting a wide net and getting a feel for the landscape. But think of them as a starting point, not the finish line. You’ll want to quickly build a list of maybe 10 to 15 companies that look promising.

But don’t stop there. Consider using a sourcing agent. True, they charge a fee. Yet top agents deliver reliable, audited suppliers. They bridge language and cultural gaps. For a first-time project, this can be an invaluable safety net. Consider it timeline insurance.

Another classic method? Trade shows. If you can attend, shows such as Chinaplas transform sourcing. In-person meetings trump emails. Inspect prototypes, interview engineers, and sense their capabilities. Also, leverage the tried-and-true referral network. Ask other project managers in your network. A recommendation from a trusted peer is often worth its weight in gold.

Separating Real Suppliers from Pretenders

With your RFQ dispatched to dozens of firms, estimates roll in. Some prices will undercut logic, others will shock you. Your task is to filter them down to 2–3 credible finalists.

How to proceed? It blends technical checks with intuition.

Begin with responsiveness. Do they respond quickly and clearly? Do they communicate effectively in English? The true litmus: are they raising smart queries? The best firms will question and suggest. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” That’s a huge positive sign. It proves their expertise and involvement. A “Sure, no issues” vendor often means trouble.

Next, dig into their technical capabilities. Request their machine list. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. A small-gear shop won’t cut it for a big housing.

Next up: the factory audit. Skipping this is a mistake. As you vet staff, you must vet suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They perform a one-day factory inspection. They confirm legitimacy, audit ISO 9001, inspect equipment condition, and gauge the facility. It’s a tiny cost for huge peace of mind.

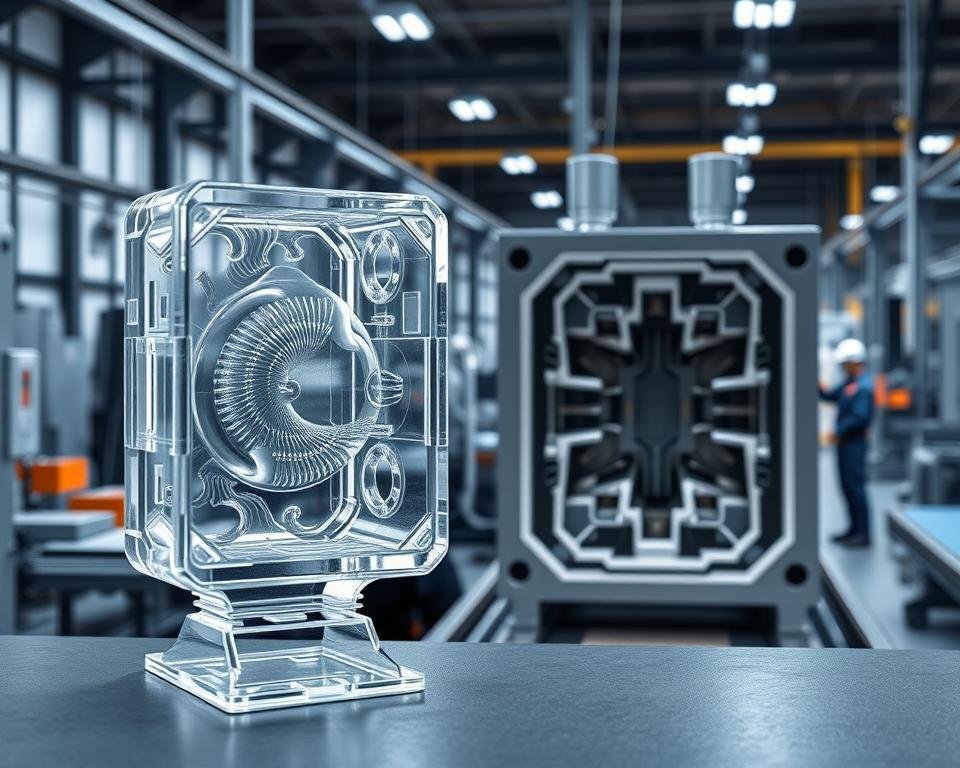

Transforming CAD into Real Parts

After picking your vendor, you’ll agree on terms, typically 50% upfront for tooling and 50% upon first-sample approval. Now the real fun begins.

Initially, expect a DFM report. DFM means Design for Manufacturability. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a two-way partnership. You iterate with their team to optimize the mold.

When you greenlight the DFM, they machine the mold. A few weeks later, you’ll get an email that will make your heart beat a little faster: “T1 samples have shipped.” These are the very first parts off the new tool. It’s your test of success.

T1 parts usually require adjustments. It’s par for the course. There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You’ll provide detailed feedback, they’ll make small adjustments (or “tweaks”) to the tool, and then they’ll send you T2 plastic mold in China samples. You may repeat this cycle a few times. Build buffer time for sample iterations.

Finally, a flawless part arrives. It meets every dimension, the finish is flawless, and it functions exactly as intended. This is your golden sample. You sign off, and it serves as the master quality reference.

Crossing the Finish Line

Receiving the golden sample seems like victory, but you’re not done. Now comes full-scale production. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. Typically, this means a pre-shipment audit. Use a third-party inspector again. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. They’ll send you a detailed report with photos and measurements. After your approval, you release the shipment and final funds. This simple step prevents you from receiving a container full of scrap metal.

Lastly, plan logistics. Clarify your Incoterms. Does FOB apply, passing risk at the ship’s rail? Or is it EXW (Ex Works), where you are responsible for picking it up from their factory door? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It hinges on strong supplier relations. Treat them like a partner, not just a line item on a spreadsheet. Clear communication, mutual respect, and a solid process are your keys to success. It’s a challenging project, no doubt. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re set to succeed.